19th april 2023 - 6:59

Aquafin is responsible for the transport and treatment of municipal wastewater in the Flemish Region. With an annual consumption up to 280 GWh, from pumping stations over wastewater treatment plants to drying of excess sludge, Aquafin takes up its social responsibility to be at the forefront of the energy transition.

Besides enormous investments in energy efficiency measures and renewable energy production, Aquafin has been active in the flexibility market more than a decade with a 2,6 MW emergency engine set-up in the ELIA mFRR ancillary service. Exploring further steps into the evermore challenging energy markets, several opportunities were pinpointed in a feasibility study first half of 2022.

What is the scope of your flexibility project in terms of assets or processes?

The biological wastewater treatment process produces excess sludge which generates biogas in about 10 central sludge digestion facilities of Aquafin. The biogas, consisting of approximately two-thirds methane, is stored in a biogas balloon being the storage capacity needed to operate in a flexible way. The biogas is combusted in a combined heat and power engine (CHP, or biogas engine) with a nominal capacity of 200 kW each.

At two pilot installations, Aquafin developed a smart control solution optimising the activation of the biogas engine based on (1) day-ahead pricing and (2) minimalization of injection of electricity production to the grid. At about 5 plants, the biogas is purified to biomethane which is injected in the natural gas grid.

Heat pumps in a range of 200 kW to 500 kW are needed as an alternative heat source for the digestion process where no CHP is available. Building upon the experience with the smart control of the biogas engines, a day-ahead pricing-based algorithm was implemented together with the commissioning of the heat pumps in the course of 2025.

Cogeneration

Heat pump

How did you go about implementing the project and delivering the expected flexibility?

As a first step of implementing demand/response in the processes of Aquafin, a feasibility study into the opportunities and barriers turned out to be crucial to get an overview of flexible processes and flexibility products. The topic was selected as one of the showcase projects within the Aquafin digital roadmap. Choosing for an internal development, Aquafin took a steep learning curve into the practical barriers of demand side response.

The cooperation of a multidisciplinary team of energy market experts, wastewater treatment technologist, the mechanical team, automatization engineers and digital wizards showed to be crucial to successfully implement a smart, cloud-controlled algorithm in an industrial environment with high security standards.

During the feasibility study, it turned out that our case was not particularly interesting for a BSP, this was due to the a rather unique industrial context and the fact that the relatively ‘small’ assets (in electric capacity) did not justify the investment needed to manage them.

As a result, at least in a first phase, we decided to design a control strategy based on day-ahead pricing and were able to do that on our own.

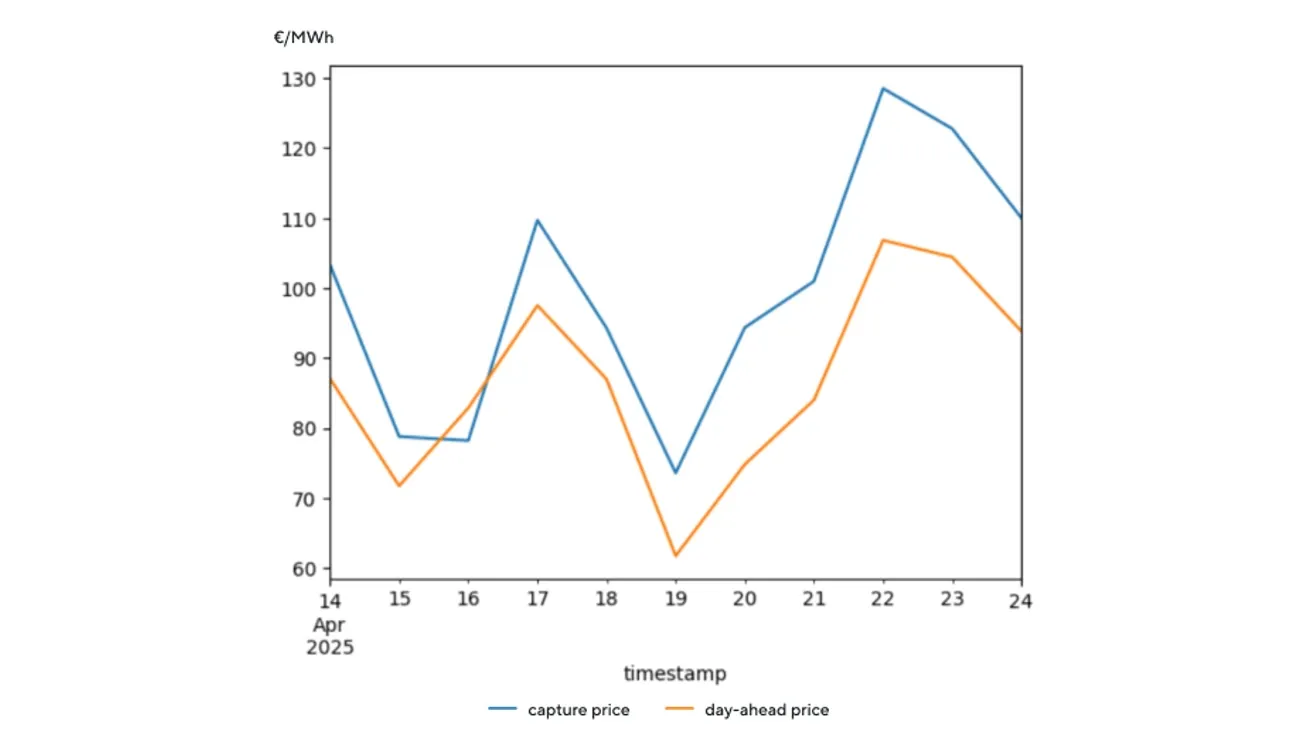

"Two years after implementation, we achieved an increase in capture rate on day-ahead prices of 10 to 20% (depending on the period of the year), which corresponds to an increase of about 10 euro/MWh of the electricity produced."

Looking back, how did the implementation go? Did you reach the expected results?

The internal development of the smart control algorithm turned out to be long and cumbersome. But two years after implementation, we achieved an increase in capture rate on day-ahead prices of 10 to 20% (depending on the period of the year), which corresponds to an increase of about 10 euro/MWh of the electricity produced. For the two pilot cases with nominal capacity of 200 kW this sums up to an annual gain of at least 5.000 euro. Besides this achievement, we also reduce injection of electricity (at negative prices), of which the monetary value is more difficult to calculate.

In addition, based on the existing experience, Aquafin will copy the smart control algorithm to five more installation totalling an installed capacity of more than 1,5 MW day-ahead controlled assets. This multiplier effect raises the annual revenue up to 50.000 euro. Furthermore, given the experience with the biogas engine show case, Aquafin was able to implement a market-based logic as a standard control strategy for more than 1 MW capacity of heat pumps starting up from 2025 as part of the upscaling of biomethane production.

The figure (below) shows the capture price of the biogas engine at WWTP Hoogstraten (blue line) and the average day-ahead price (orange line) for a 10-day period April, 2025.

We decided to develop our control strategies in-house, which required us to navigate a challenging learning curve. I recommend that companies with multiple sites, looking to add flexibility to their processes, understand that building cloud-based process control in-house is much more complex than working with standard smart home applications. For advanced control mechanisms of market parameters, we would not hesitate to engage the services of a specialist company with specific experience to accelerate the project.

+5 000 €

yearly revenue

Extra yearly revenue for two 200kW CHP installations with DA optimization.

Latest case studies

Let's hear what some professionals have to say about their use of flexibility services